Quality Management made as Simple as ABC

Meet Effivity QMS-the most advanced, adaptable, 💸budget-friendly and 🫱🏻🫲🏽collaborative tool for

optimizing quality management.

Streamline and automate business processes with our dynamic QMS

software that evolves with your needs.

Pre-configured and highly result-oriented, Effivity QMS is truly a quality software for achieving excellence in quality management system.

Trusted by 3000+ happy customers who are leading the world

It’s not just Software.

But the future of Quality Management

With a no-code/low-code approach, Effivity QMS makes quality cycles 100% effortless,

paperless and errorless

Our interface adopts a drag-n-drop approach backed by strong visuals for instant visibility and flexibility. Endless customization capabilities make it a breeze to

Create &

Customize Forms

Fields

Workflows

Reports

and everything in between.

With Effivity, you take control. Not burden.

A Modern QMS for Modern Needs

Effivity’s Quality Management Software is a unified platform for diverse needs. Tap into the power of an automated quality expert to manage governance, risks, compliance, documented information, internal audits audits, calibration, maintenance, customer complaint, training, objectives etc.

Experience efficiency like never before

Conduct audits, approve documents, raise/close non-conformities, carry out inspections, track KPIs, assign tasks, automate workflows, generate records, and communicate with teammates - all effortlessly

Stay Connected,

Stay Successful

Maintain quality from anywhere in the world with our cloud-based quality management software. Access anything and everything via our mobile app remotely-from the field, your home, or even your favorite cafe!

Seamless Control at your Fingertips with 30+ integrations

Get all your tools in one place to maximize productivity. Connect and sync existing systems (third-party apps, CRM, ERP, etc.) with Effivity QMS and turbocharge your business

Ensure business continuity with Automated Backups

Keep your business up and running even after disruptions. Protect critical data, minimize downtime, and recover swiftly from disasters with automated data backups

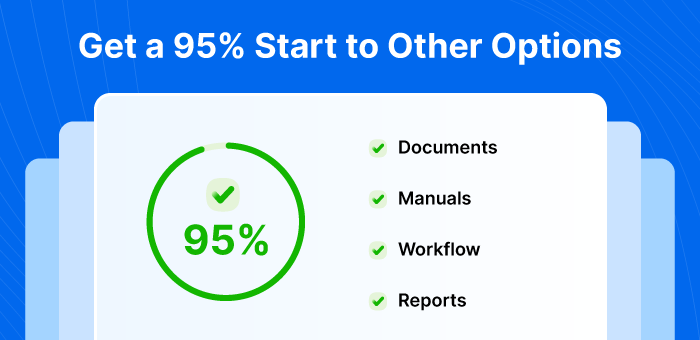

100+ Pre-configured QMS Workflows

Access our library of more than 100 ready-to-use templates and workflows to get a 95% head start. Enjoy robust compliance and quality management from day one

Quality Management Brochure

Dive into Effivity ISO 9001 software modules, features and capabilities to unlock its true potential.

Compliance has never been this easy

Effivity QMS is a one-stop destination to build, certify, maintain, and enhance your quality compliance.

Schedule, Conduct, and Track Audits with Precision

Cut the audit-related admin hassle and get accurate results. Set trigger actions, monitor audit status, capture findings, and visualize insights to implement the best corrective measures.

A Single QMS Software for Multiple Quality Standards

Comply with ISO/IATF/AS/GMP/customer/ regulatory standards with a unified interface.

Automation and Reporting at its Best

Powerful reminders, notifications, and auto-escalation to complete tasks effectively and on time. Real-time dashboards with comprehensive data analytics and graphs further facilitate quick decision-making.

Implement & Maintain

ISO 9001 QMS with Effivity

Effivity’s Quality Management Software fits every business-small, medium, and large. We offer

numerous modules

covering different aspects of quality management. Pick your favorites, and

pay only for the features you want in the QMS!

Effivity quality management solution allows you to define the communication process for your QMS, including internal and external communications.

Read more

A Thousand Tasks.

A single tool

Effivity’s QMS software is an all-in-one platform for everything quality-products, services, and processes. Get it today to implement, maintain, and improve your quality management system.

Schedule a Free Demo

Why Choose Effivity

Quality Management Software?

Imagine a personal quality expert tailored to your business needs.

That’s exactly what

Effivity QMS is!

Redefine Quality with

Effivity QMS Automation

Free trials, quick deployment, and swift data migration. Achieve business excellence with stellar onboarding and customer support!

Get a free 2-week trial to explore our features. Add modules, build your subscription plan, and activate your subscription through bank transfer/ credit card.

Activate your account within seconds! Assign roles, configure access control, and even set up a multi-site structure.

Provide detailed training to admin and users on Effivity QMS. Our simple, intuitive interface and zero learning curve guarantee quick proficiency for all.

Roll out your QMS within a few days. Customize it to improve its efficiency and see the business performance skyrocket.

Phone, email, or online meeting. We’re always here to help you out.

Hear it from our customers

Don’t believe our word? Let our customers speak for our quality:

Great software that lays out all ISO requirements to fill in. It helps guide implementing an ISO system, not just a software to house documents/records.

Michelle F - Twist Bioscience

User friendly and innovative. 1. lessen my paper works 2. easily maintained company system. 3. It's updated as per the convenience of user. 4. easy system monitoring.

Lorraine B - Logistics and Supply Chain

I absolutely love this software. Gained a huge new customer in the market and were able to begin our ISO Certification journey.

Linda S. - Manufacturing Engineer

Enjoy limitless access:

anywhere, any screen, any time

Effivity QMS is responsive and device-independent. You can log in to your account via a web browser or download our app. PC, laptop, tablet or mobile phone-we’re everywhere.

Free Trial Today